Background

How it all started

Initial Interest In Solar From Door Knockers

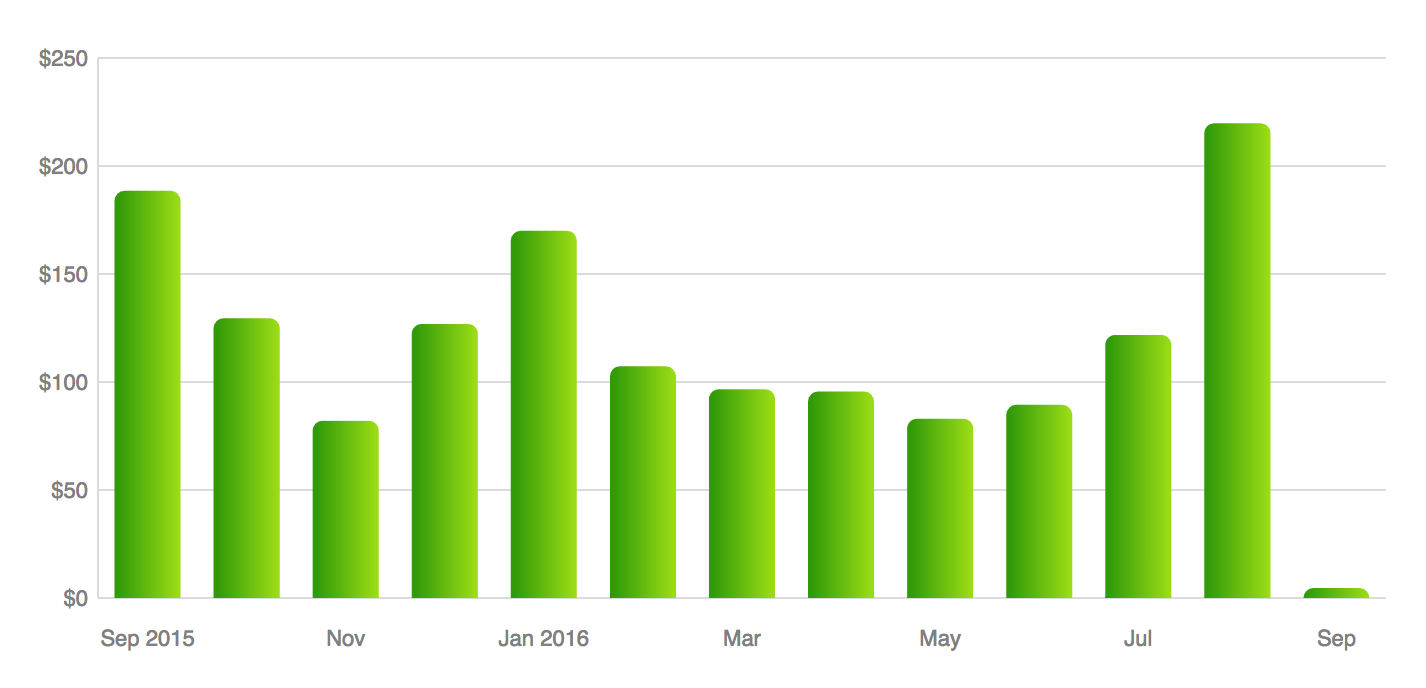

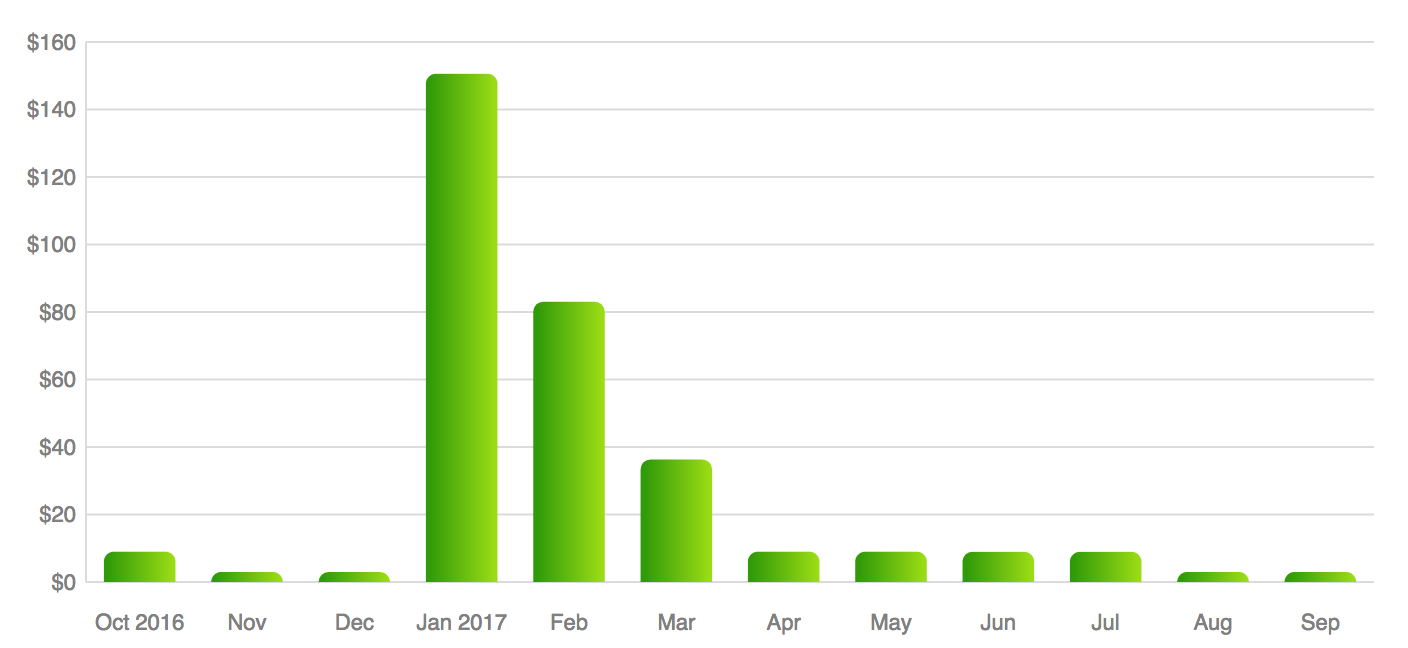

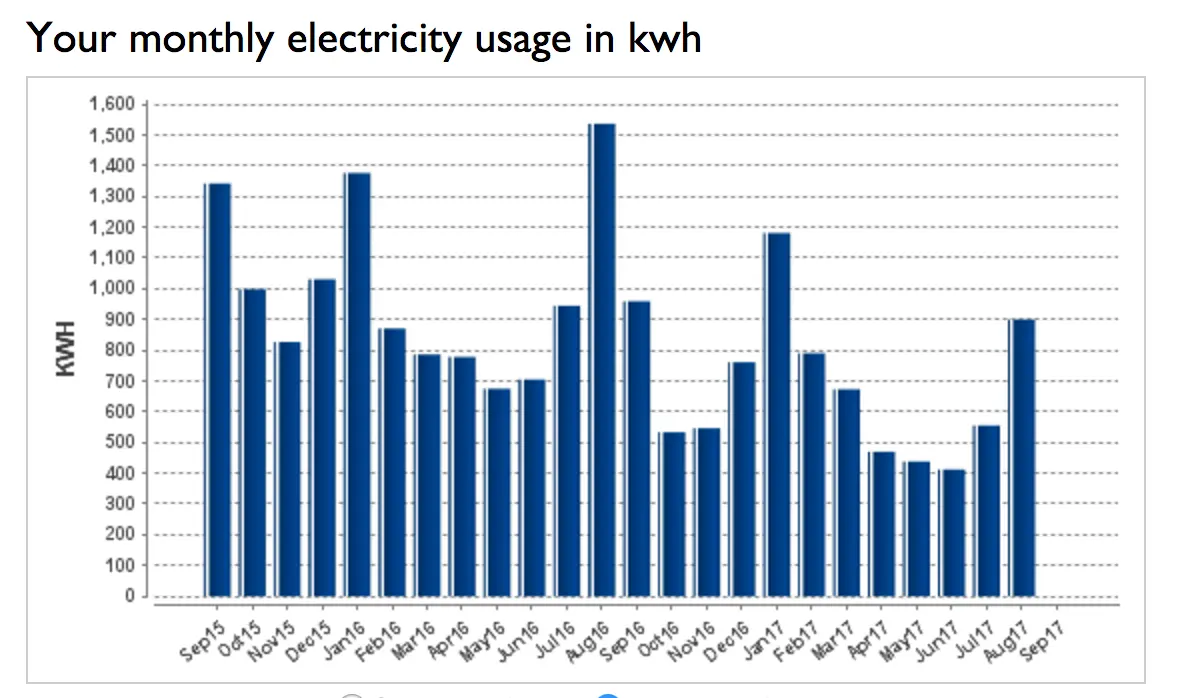

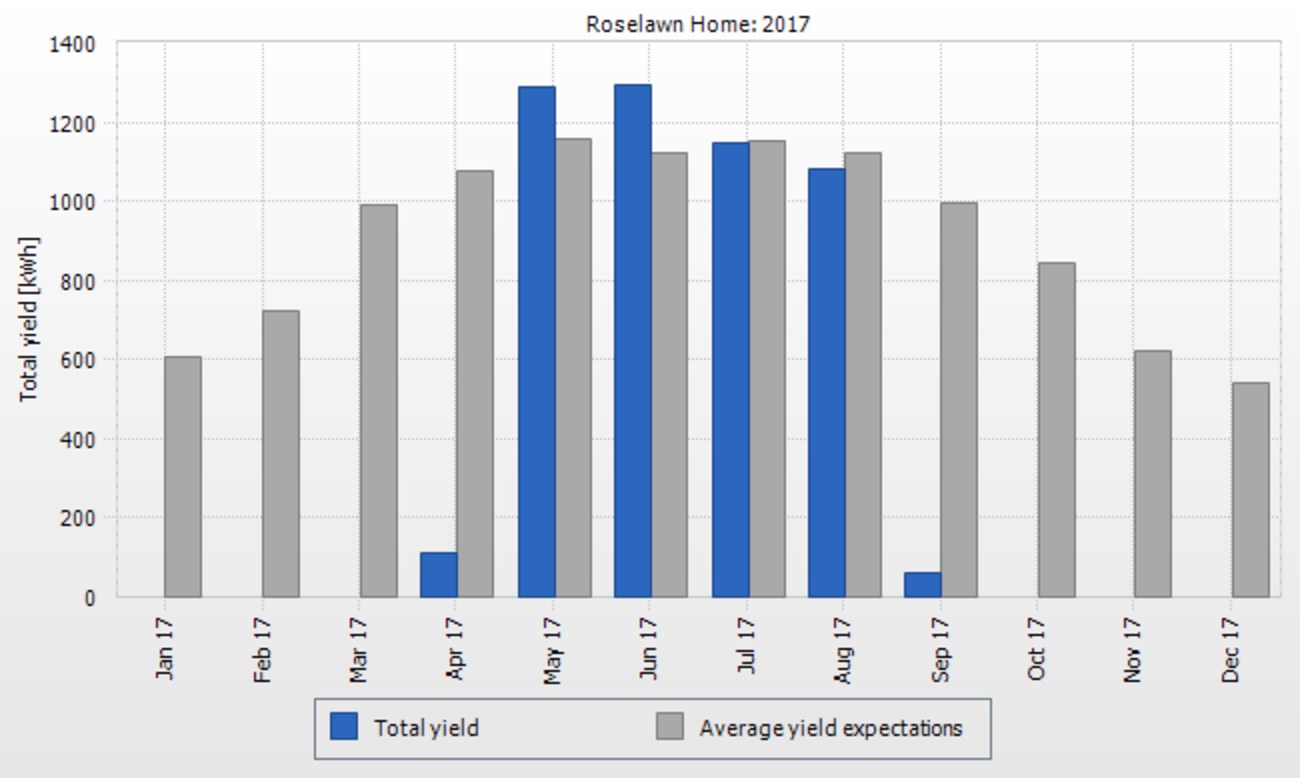

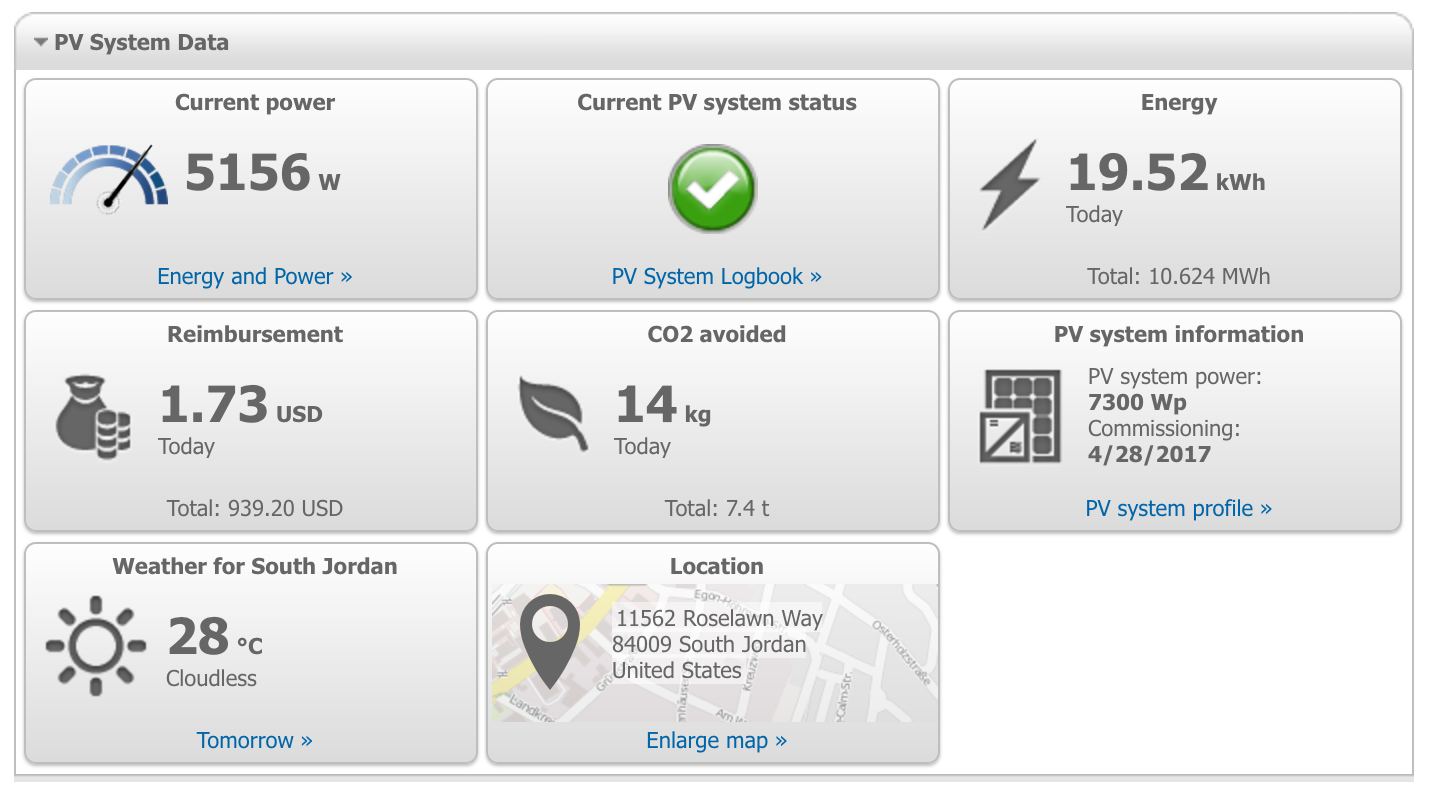

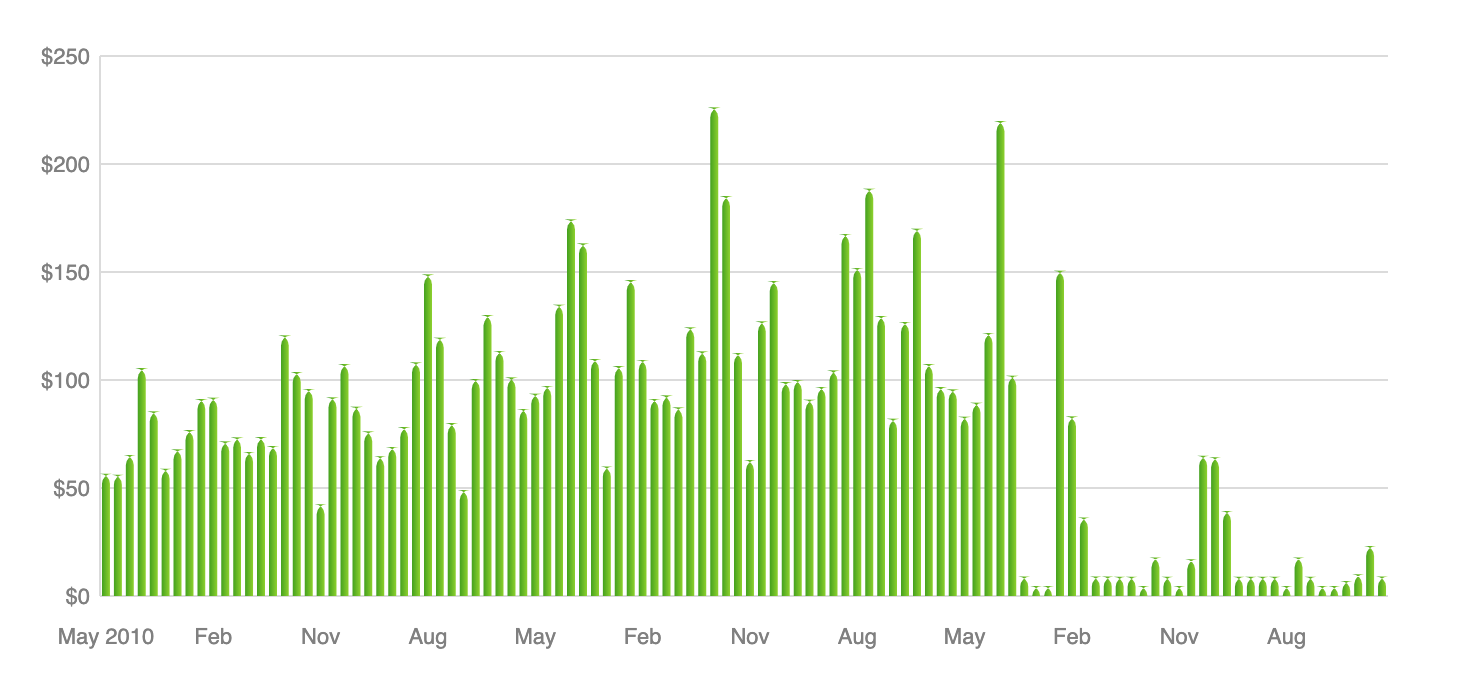

I got interested in installing solar panels on my roof in South Jordan, Utah, not only to save the planet, but also to save money and eliminate any monthly bills I could. I got some quotes from Vivint Solar, Legend Solar, etc. Most of them quoted me a 7 kilowatt system (which is necessary to produce the 12,000 kilowatt-hours I use in a year for my 3400 square foot home). Most of them said it would be about $25,000, and after tax credits (federal and state), it would be about $16,000. This sounded okay, but with my bill of $100-$150 per month, it would have taken about 8-12 years to break even.

Considering Doing It Myself

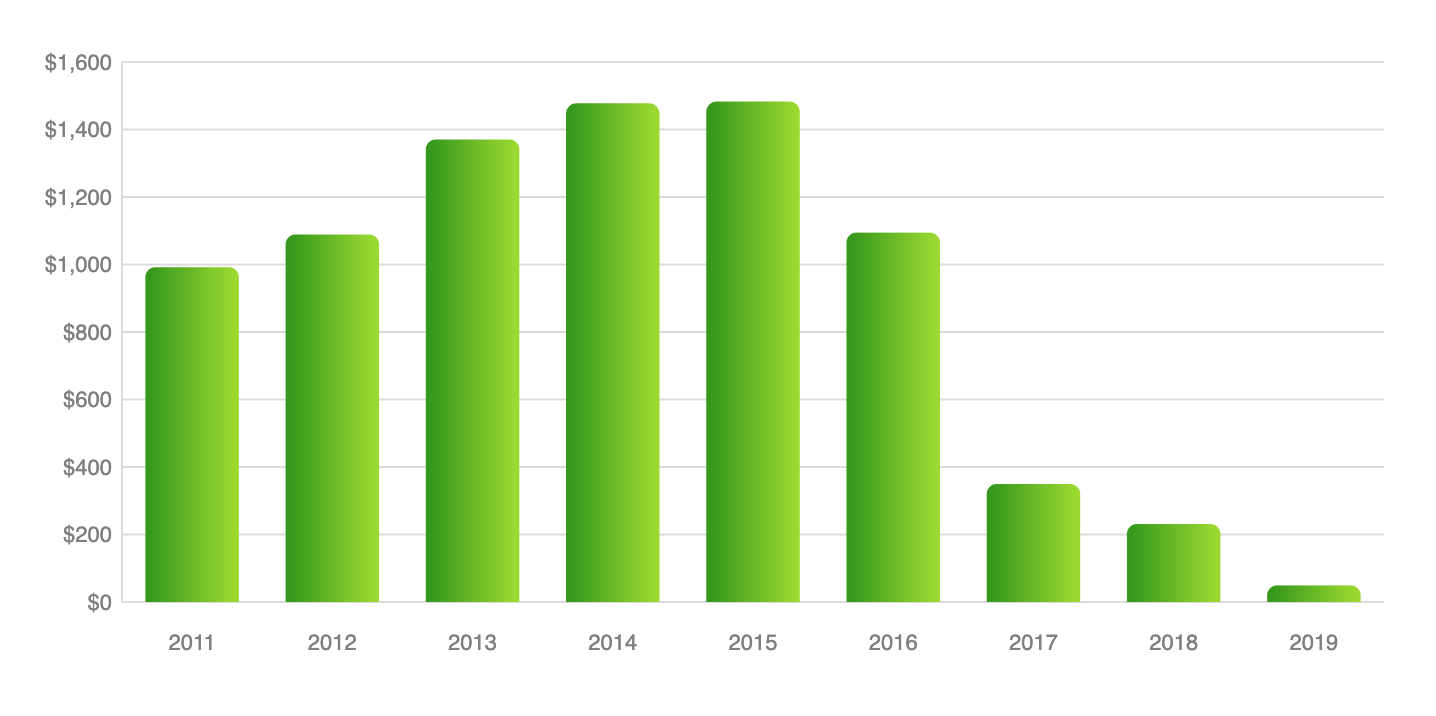

That is when I started looking into doing it myself. After some investigation, I discovered it would only cost about $8,000 total, and then $4,000 after tax credits – one-fourth the cost and with a break-even of only 2-3 years! It is a great time to do it because the costs continue to go down on the panels and equipment, but the tax incentives/credits are still pretty high (but will decrease in 2019), so the overall cost to you as a homeowner is quite low. This article describes how I did it at this cost.